Integrated solutions for EC – ATEX marking of equipment, machinery and plants

Our services for Directive ATEX 2014/34/EU

3p Safety provides manufacturers with 15 years experience in the ATEX area with analysis of compliance and certification of machinery and equipment intended to be used in potentially explosive atmospheres due to the presence of flammable gases and fluids, combustible dusts and fibres.

Mechanical eqipment

Skids or sets of

equipment

Machines

Electrical

equipment

We provide a complete, modular service which goes from initial analysis, zone classification, ATEX and IECEX certification of machinery, electrical and mechanical equipment, inspection and audit of compliance in the field on machinery and plants, assistance in relations with notified bodies, technical department training and technical-legal assistance.

ATEX and IECEX marking, technical file, instructions, translations.

Zone classification and risk ignition analysis

Inspections and audits

Electrical equipment

and instrumental measures

Training, purchase contacts

management,

technical-legal assistance

Audit Atex & Safety meeting

-

- Market context analysis and definition of II 1, II 2 or II 3 marking category and of EPL (Equipment Protection Level) on the basis of commercial and technical economic assessments

- Analysis of directives and standards applicable to equipment, machinery and plants for the Machinery directive or PED application.

- Safety meeting with suppliers and customers to define and analyse supply and contractual specifications

- Technical audit of compliance of equipment or machine with drafting the intervention report

Analysis of ignition risk on equipment and explosion risk on machinery and plants

(ignition risk assesment & explosion risk assesment)

- Definition of use limits for equipment or machinery on the basis of areas with an explosion hazard, operating and process conditions

- Identification of potential and effective ignitions according to EN 1127-1

- Analysis of ignition risk in compliance with the standards EN 13463-1, EN 80079, EN 12100

Design of safety functions

- Definition of safety architecture for electrical / electronic and pneumatic / hydraulic systems

- For complex machines and lines with a high number of I / O safety, functional logic safety matrix processing

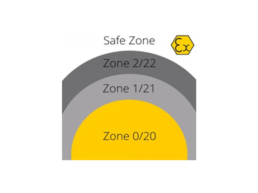

Classification of areas with risk of explosion on machinery and plants

- Use limits analysis and process operation parameters

- Classification of explosion risk zone due to the presence of flammable fluids or gases according to EN 60079-10-1 and the presence of combustible dusts and fibres according to EN 60079-10-2.

Advisory and assistance in mechanical and electrical design phase

- Assistance in designing suction systems, inertisation and integration protection systems

- On the basis of the PLr / SILr we are able to perform the reliability verification calculation achieved in compliance with the EN 13849-1 (PL) or EN 62061 (SIL) standards of the ATEX safety functions.

Purchase control and integration of electrical, mechanical equipment and ATEX protection systems

- Assistance in validating the purchase of all supplies in the ATEX environment

- Verification of choice and conformity of electrical and mechanical equipment installation according to EN 60079-14, EN 80079-36, EN 80079-37 with the drafting of an intervention report

Assistance in the management of tests and trials

- Identification of the necessary trials and any need of accredited laboratories

- Execution of thermal, air speed, electrostatic charge tests and issue of measurement reports

Instructions for use manuals and translations in target languages

- Advice for in the drafting of instructions for use

- Graphics of details

- Translation of documentation in target languages

Advice for creation of the technical file

• Advice for in the drafting of instructions for use

• Graphics of details

• Translation of documentation in target languages